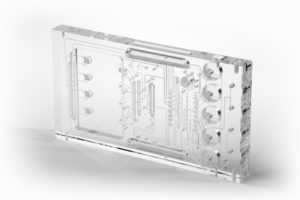

Diffusion Bonded Fluidic Manifolds

If you need a plastic fluidic manifold, with leak-proof, sealed tracks and chambers between layers without the use of any adhesives or sealing gaskets, then diffusion bonding is a prime candidate for your application. It allows you to create smooth, curved channels, interfacing over several layers to produce complex, multi-channel fluidic manifolds. They are equivalent to PCBs but with fluid channels. Heat and pressure is used to create a molecular bond between the layers to form a solid block with up to 97% of the tensile strength of the original parent material.

Why Carville?

Carville first pioneered diffusion bonding of plastics in the 1960’s and has been innovating the processes ever since. We now use our unique, High Accuracy Diffusion Bonding (HADB) to produce very accurate and highly repeatable bonded fluidic manifolds for global customers in medical, life science, diagnostics and industrial applications. This is coupled with our deep heat treatment knowledge and high precision CNC machining. We can bond channels as small as 150microns deep with this HADB technique.

Materials used in diffusion bonded manifolds

Carville bond manifolds in both Acrylic/Plexiglas PMMA and Ultem/ Polyetherimide (PEI) materials. No adhesives or contaminants are used, leaving you with a solid plastic manifold suitable for sensitive fluid applications.

Benefits of using Diffusion Bonded plastic manifolds

Fluidic Manifolds are great at replacing multiple tubing and connections for a number of sub-systems for both liquids and gasses with a single component. Multiple layers are possible, with smooth, curved profiles to let you decide how external components can be mounted and aligned. Bonded manifolds offer major advantages over traditional cross-drilled or gasket sealed manifolds. Key benefits include:

- Reduced servicing costs

• Reduced assembly time and costs

• Improved reliability

• Reduced component count and costs

• Significant reduction in potential leak points

• Eliminate the potential for incorrect connections in assembly and servicing

• Reduction in dead volumes and no need to plug channels

• Visualising of system operation and optical sample analysis

Diffusion bonded manifolds can be used in a range of applications and fluid types including air/pneumatic, reagents, sample fluids, waste & cleaning fluids. Users refer to these in a number of different ways including plastic manifolds, bonded plastic manifolds, plastic pneumatic manifolds, plastic air boards, plastic valve manifolds, plastic medical manifolds and plastic flowcells.

Solvent Bonding

As an alternative to Diffusion Bonding, Carville also offer Solvent bonding which is a simpler process suitable for larger parts with bigger channel cross-sections and large cavities

Read our latest article: