Plastic fluidic manifolds have been used in life science applications for over 30 years, however it has only recently seen a significant growth in their application, as the technology, sophistication and repeatable quality of bonded manifolds has increased and the value better recognised.

Multi-Layer Fluidic Manifolds Flexibility

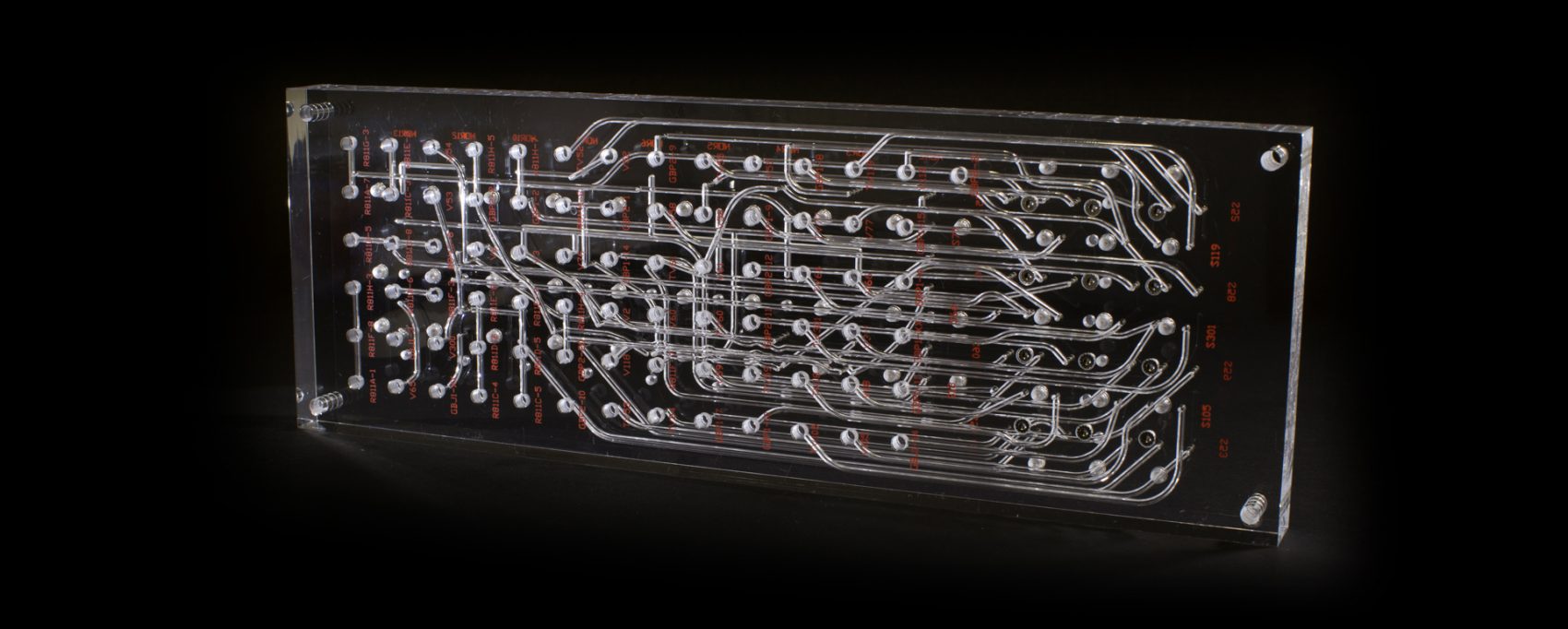

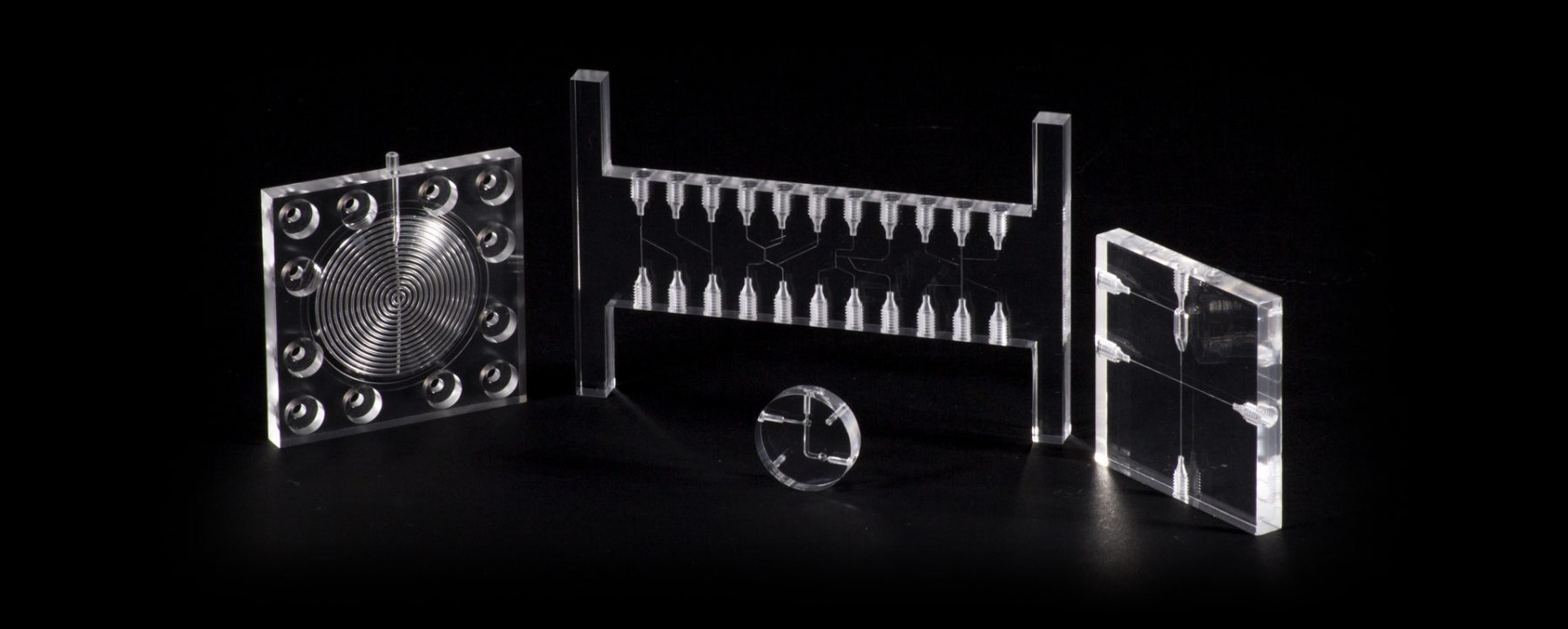

Conventional manifolds in metal or plastic predominantly use cross drilling to achieve the fluidic paths. These can be useful for some applications but highly restrictive for anything more than simple systems. The development of multi-layer, fluidic and diffusion bonded plastic manifolds opens up massive flexibility in three dimensions, with channels crossing many plains to produce vast networks of fluidic manifold channels, for multiple sub-systems, in a single manifold. The scope of potential channel sizes and shapes is also almost infinite including tapering, multiple cross-sections, different profiles, mixing chambers, flow metering and sample analysis sections. The integration of microfluidics is also increasing, with channel profiles down to 150 microns.

Bonded Fluidic Manifolds System Design

The key to system design with bonded manifolds, is to use to their vast capabilities to design as much of the system complexity as possible into the fluidic manifold and remove it from the rest of the system. In this way, most of the system complexity is in a single, highly repeatable component, analogous to a PCB or microchip. You can also build many of the other system components into the manifold such as sample heaters, mixing flees, flow sensors, connectors, threaded inserts and tubes. Engraving the external connection identities into the plastic will also act as a permanent aid to final assembly and servicing.

High Accuracy Bonding (HAB)

To ensure accuracy and repeatability of manufacturing fluidic manifolds, Carville have developed a unique method called HAB to carefully prepare the pre-bonded surfaces and accurately control the bonding process. This process allows the very fine detail of micro fluidic channels to be precisely paired and the depth accuracy maintained down to a few microns. It also ensures no de-lamination as the parts are bonded at a molecular level like a weld, however the HAB method means the join remains transparent and almost entirely invisible.

Fluidic Manifolds – The Clear Advantage

The transparency of plastics such as Plexiglas/Acrylic makes it ideal for many life science applications, as a clear optical path to a substance is often vital. Optical based sensors are widely used for sample analysis and sample speed detection in applications such as analytical chromatography and DNA analysis. Ultra Violet (UV) or Infra-Red (IR) detection systems are often mounted close to the transparent sample chamber in the manifold for monitoring, control and analysis. It is also extremely useful for visual inspection to monitor systems and easily identify issues or blockages. Carville’s processes of precision machining combined with physical and vapour polishing enable even very fine channels to have high optical clarity for these systems.

Life Science Applications

Bonded fluidic manifolds in materials such as Acrylic (PMMA) and Ultem (PEI) are becoming far more widely used recently in many In Vitro Diagnostics (IVD) applications both in the laboratory and hospital Point of Care (PoC). Typical uses include clinical chemistry, ELISA, haematology, pathology and many diagnostic applications. Integrating manifolds with arrays of different valves means increasingly complex manifolds are being entrusted to deliver functionality such as dosing, pneumatic control, cleaning cycles, reagent mixing, flow analysis, particle separation, bacteria analysis and many more. Proving that they stand the test of time, a Carville fluidic manifold with integrated peristaltic pumps has been used in a client’s blood gas analysis system for over 20 years now.

For further information or to discuss an application, please contact us.