A growing trend is occurring in the food and beverage industry with respect to the use of optical plastics, especially Acrylic/Plexiglas/Perspex (PMMA) and Polycarbonate. The benefits of advanced vision systems and old fashion physical visual inspection for both sample analysis and continuous monitoring, are being increasingly realised with optically clear components. There has also been a growth in the adoption of multi-layer, Acrylic fluidic manifolds for their flexibility and optical characteristics.

Optical Sensing Applications

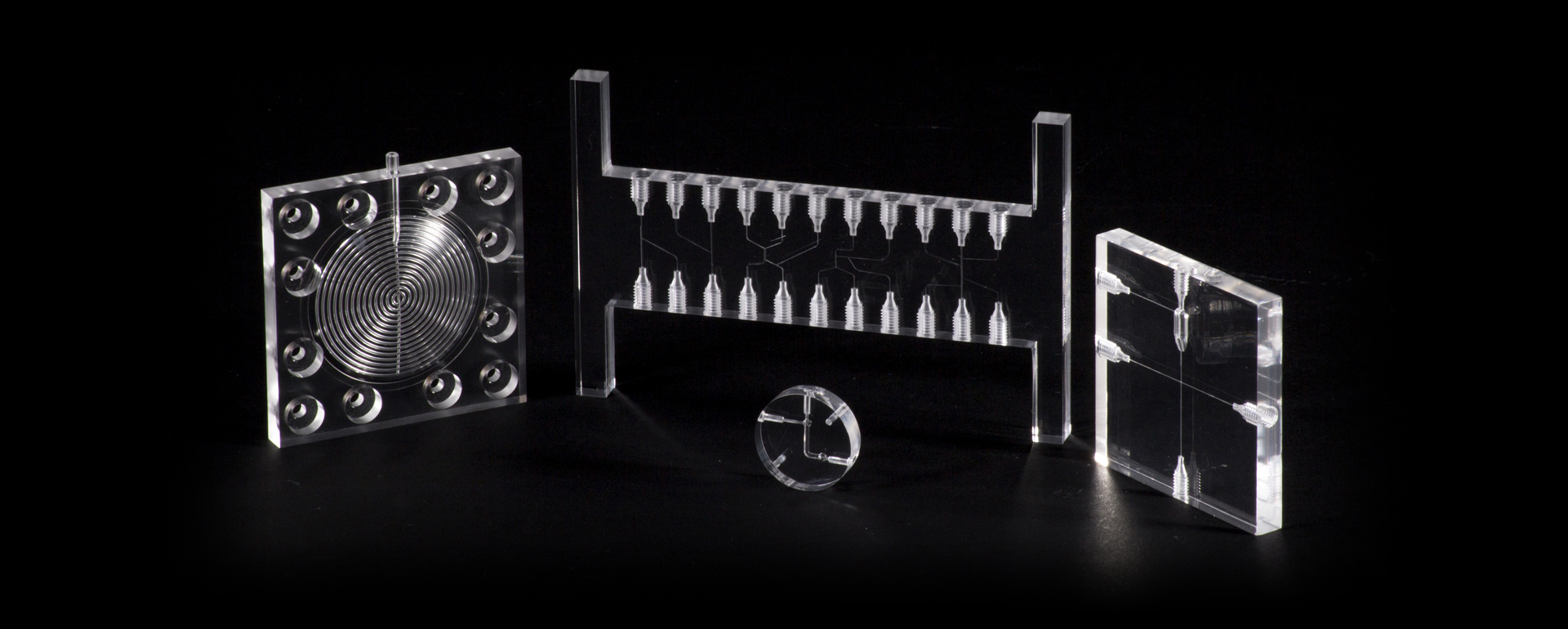

Sample testing for composition, purity, contaminants and critical factors is a vital part of most industries in this area, including milk, other dairy, feed, oil and beverage production. This testing is often achieved using non-contact, light-based emission and receiving sensing technologies at various wavelengths. These all require a clear optical path directly to the substance, which can be achieved using clear plastic components. For example, very subtle but important characteristics in wine and beer production are monitored using Near Infrared (NIR) and Infrared sensors, and similar sensors are also used for Ketosis level monitoring in milk. Precision-machined acrylic components are being increasing used for these applications as a single component can be manufactured to channel the fluid, mount the sensor and integrate with the complete system. Carville have been providing precision plastics to this industry for many years, supporting a number of the leading companies in this field in both Europe and the USA. Clients also like the assurance that the materials are food safe so Carville source FDA 21 CFR 177.1010 approved Acrylic and 177.1580 approved Polycarbonate that are Food Contact Substance (FCS) certified.

Machined versus moulded plastics

Precision-machined plastics have many advantages over injection-moulded solutions for these kind of applications, which include the following:

Huge flexibility to create complex solutions with multiple wall thicknesses and intricate details.

Superior optical properties

Low investment cost

No draft angles required

Frequent design modifications possible

Fabrication options

Multi-Layer fluidic manifolds

Vapour and manual polishing

No injection mould inlet gate or ejector marks

Moulded components tend to be more suitable for high volume components where unit cost is particularly critical and the above factors are less important.

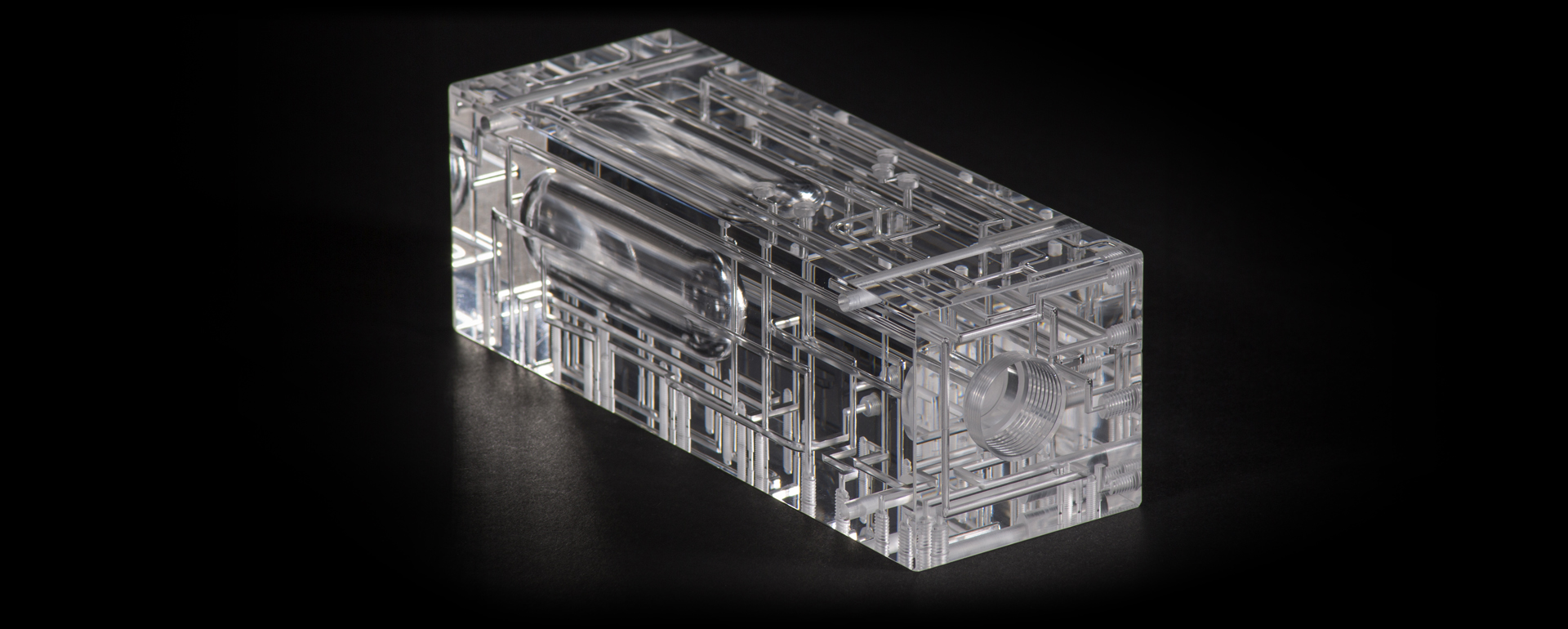

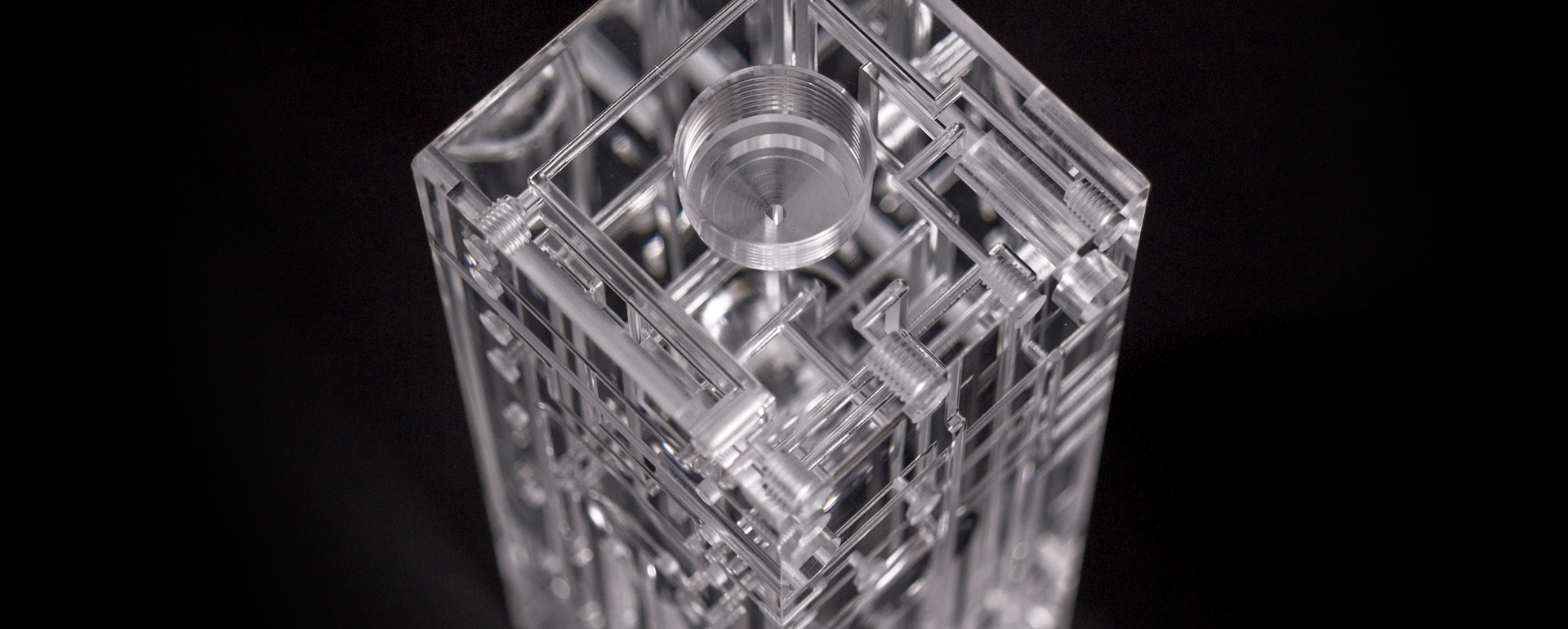

Fluidic Plastic Manifolds

Although multi-layer plastic manifolds have been around for several years, there has been a recent upturn in their application as the range of benefits are being realised, especially for food sample analysis. The design flexibility of these manifolds is vast to incorporate many functions and channels that are traditionally achieved with multiple tubes, connectors and mountings. The advantages are considerable:

Improved system serviceability andreliability

Reduce assembly time and costs

Reduce leaks

Weight reduction vs metal

Eliminate incorrect connections

Optical paths for sample analysis

Reduction in dead volumes

System faults or blockages are easy to detect

Manifolds can be used as part of a chassis

Multiple component integration such as valves, sensors and pumps

Carville’s High Accuracy Bonded (HAB) manifolds also provide a fully repeatable solution to tight tolerances, even with microfluidic channels. The electrical insulation properties also offer advantages over stainless steel solutions by making the integration of electronic fluid sensors far easier, such as conductivity, purity or specialist CO2 recovery elements. For further information or to discuss an application, please get in touch.