Heat Treatment of Plastics

The heat treatment of plastics (known as Annealing and Normalising) is essential to ensure tight tolerances are maintained during precision machining, bonding and polishing and to avoid cracking and crazing. Heat treating also eliminates internal stresses and ensures better mechanical and thermal properties. Without this essential heat treatment process, it is virtually impossible to produce accurate plastic components to precise tolerances.

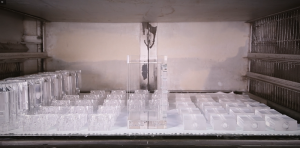

The majority of times you see cracking and crazing in plastics such as Acrylic/Perspex/Plexiglas (PMMA), Polycarbonate (PC) or Ultem (PEI) is due to inaccurate and incorrect heat treatment cycles. Carville have a high level of expertise and experience in the heat treatment of plastics, able to accurately adjust the process for specific plastic materials, thicknesses and applications. We have multiple, in-house heat treating ovens to perform these heating processes, all of which have full data recording capabilities to ensure every process and batch is fully traceable.

Heat Treating Acrylic

Cast Acrylic has a coefficient of thermal expansion at 7.7 x 10-5 m/(m ⁰C). It is possible to produce a 100mm diameter component to a tolerance of +/- 0.1mm, however, a change in ambient temperature of 15⁰C would take this component out of limits. Consideration should be given to working tolerances and the end application when selecting the correct plastic materials and considering the use of plastic components. To ensure component stability, it is important to heat treat both the base material and finished component to ensure that they are stress free and will remain stable over a long period of time.

Normalising & Annealing

Normalising gives the plastic a uniform and fine-grained structure. The process is used to obtain a predictable microstructure and also gives assurances of the plastic’s mechanical properties.

Annealing is the second part of the heat treatment process and changes the microstructure and mechanical properties of the plastic. Typically, annealing is used to reduce the hardness and helps eliminate internal stresses and ensures better mechanical and thermal properties.

The correct heat treatments of the initial plastic materials along with the finished machined components are essential to ensure a long and reliable component life and performance.

Why Heat Treat Plastics?

The most cost effective way to produce materials such as Acrylic, PEEK or Ultem is to use either a casting or extrusion process. Although cost effective, cast acrylic or extruded engineering grade materials such as PEEK or Ultem can be highly stressed and have a surface skin which can pull and distort components during and after the manufacturing processes.

To ensure stable dimensions and a long life for precision machined component parts, it is essential that materials are correctly heat treated to remove internal stress. Carville source material oversize, skim to break the surface skin and then heat treat to remove the internal material stress. Carville will not manufacture machined plastic component parts without fully heat treating the base material at the pre-production stage.

What is the Impact of Heat Treatment?

On plastic materials such as acrylic (PMMA), the initial heat treatment, or normalisation processes, can result in material shrinkage of between 2% and 4%. This movement is a result of the material relaxing and releasing the internal stresses that have developed during the casting or extrusion processes.

Does Carville Heat Treat All Parts?

All plastic materials used by Carville are normalised using controlled heat treatment processes before any machining operations take place.

During the production process, all components are stage annealed to remove any stresses which may have been induced due to the machining operations.

Material normalisation and inter stage annealing ensures that acrylic and plastic components produced by Carville will have minimal material stress and will offer a long and reliable performance.

How Long Does Material Heat Treatment Require?

Subject to the component size, and the volume of material removed, the heat treatment processes may be performed several times during manufacturing operations. These heat treatment processes can add several days to the component manufacturing process which is why Carville’s lead-times are quoted in weeks rather than days.