Carville started to precision machine Perspex Acrylic and Rohm Plexiglas in the 1930’s and has over 80 years of experience in precision plastic machining. We produce CNC precision machined plastic components in various engineering grade plastics including:

• PolyMethyl MethAcrylate (PMMA – Acrylic)

• PolyCarbonate (PC)

• PolyOxyMethylene (POM – Delrin)

• PolyPropylene (PP)

• PolySUlphone (PSU)

• PolyEtherImide (PEI – Ultem)

• PolyEther Ether Ketone (PEEK)

• Poly Vinlyc Chloride (PVC)

Although there is no definitive meaning of precision plastic machining, we see it as accurately and repeatedly producing challenging parts in terms of geometry, tight tolerances, finishes and optical clarity when required. Meeting these requirements on a daily basis requires high performance machines and tools, experience, robust and efficient processes, and a culture of accepting only the highest quality.

Precision Plastic Machining Process

Precision machining plastics is very different to machining metals, and requires a very different approach in terms of tools selection, cutting paths, numbers of passes, cutting speeds, pecking, reaming and multiple other factors. The first step to this is a precise heat treatment protocol for the plastics to pre-shrink the base material and de-stress it. Throughout the machining processes we also conduct many first-off inspections and annealing cycles to ensure quality is built into and maintained in all components. When dealing with transparent plastics such as Acrylic / Plexiglas / Lucite (PMMA) or Polycarbonate, any minor errors or marks are immediately visible, so visual inspection stages are built into the process at multiple points.

For the final inspection we use a mix of gauges, Coordinate Measuring Machines (CMMs), machine vision systems, stencil templates and bespoke inspection and test equipment are used to ensure 100% conformance to specification.

In additional to specialising in Perspex Acrylic / Rohm Plexiglas / Lucite (PMMA), Carville also heat treat and machine components in a wide range of engineering plastics. These include many standard engineering grade plastics such as polycarbonate or high performance materials such as Ultem (PEI) or PEEK. Carville are experts in a versatile range of techniques and methods of Precision Plastic Machining. Different materials present different challenges, for example precision machining of PEEK and especially POM (Delrin) requires specific strategies and deburring techniques to avoid issues such as burr flaps on cross drilled intersections.

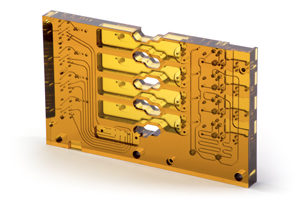

Cross-Drilled Fluid Manifolds

Precision liquid or gas manifolds are an excellent method of fluid control for anything from simple to complex systems. Carville manufacture both simple and demanding cross-drilled manifolds from many different plastic materials and work with valves from all the world’s major valve suppliers. For more complex manifolds, we often recommend using diffusion bonded manifolds which offer many advantages over cross-drilled. See our article for more background.

Quality

Carville precision machine plastic components for customers operating in the medical, specialist industrial and high end consumer markets. The Carville facility has a reputation for supplying quality plastic component parts to our customers on time, right to drawing and at competitive prices.

Carville have documented manufacturing procedures to track customer’s products throughout the manufacturing process and the Carville facility was accredited with ISO 9001 in 1992.

Supply Agreements

Carville is considered a category A supplier by many of our customers. To support these customers, and the fluctuation in their build plans, Carville operate scheduled supply agreements which allow customers to call finished goods from stock.

Schedule supply agreements allow Carville to optimise the manufacturing process, reduce the manufacturing costs and ensure the most efficient supply of finished parts to our customers.

Request a Quote

Carville operate both AutoCAD and Autodesk Inventor software packages at our manufacturing facility. These drawing packages allow Carville to review customer drawings and offer quotations for machined plastic components, fabrications and assemblies.

Customers who require a quotation from Carville should send 2D drawings (.pdf or .dwg) along with a 3D model (.stp) for Carville to review. Drawing files, along with the required part quantity, should be sent to sales@carville.co.uk

Carville will offer a quotation along with feedback on the parts suitability for manufacture, opportunities for part optimisation and opportunities for part cost reduction.